Max. Die cutting Speed: 450 times / min

Max. Width of Die Cutting: 350 mm/450mm

Precision of Web Guiding: ± 0.10 mm

Gross Power: 14 kW

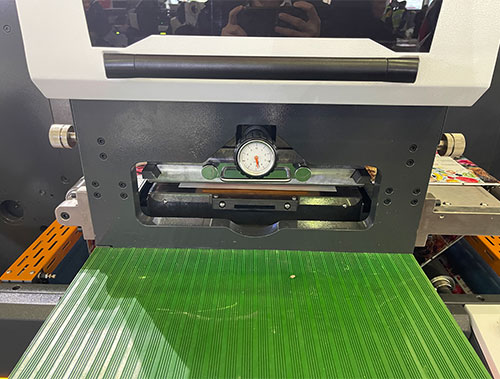

HSMQ-350-450 High Speed Flatbed Die Cutting Machine is a stable, high-speed automatic flatbed die-cutting equipment that supports large-format materials with max. unwinding/rewinding diameter of 700 mm.

High-efficiency and high-speed die-cutting capability: With a maximum die-cutting speed of 450 times/minute, it can greatly improve the efficiency of mass production.

Advantages of large-size material processing: The maximum unwinding/rewinding diameter is 700mm, which reduces the frequency of roll change and is suitable for continuous processing of large rolls.

High-precision processing guarantee: The paper guide accuracy is controlled at ±0.10mm to ensure the precise size and neat edges of the die-cut finished products.

|

Descriptions |

Parameters |

|

Max. Die cutting Speed:

|

450 times / min *1 (approx. equals to 120 meters / min) |

|

Max. Unwinding Diameter: |

700 mm |

|

Max. Rewinding Diameter: |

700 mm |

|

Max. Width of Die Cutting: |

320 mm/420mm |

|

Max. Length of Die Cutting: |

350 mm/450mm |

|

Precision of Web Guiding: |

± 0.10 mm |

|

Gross Power: |

14 kW |

|

Voltage of Power Supply: |

380 V 3P |

|

Weight: |

3000 KG |

GET A QUOTE