Flexo paper label printing machine boasts independent servo drive and ±0.1mm precision. With 150m/min max speed and 100m/min die-cutting speed, it fits 0.38mm materials (excluding shrink film). Intelligent control and fast plate change boost efficiency—ideal for food, logistics, cosmetics labels.

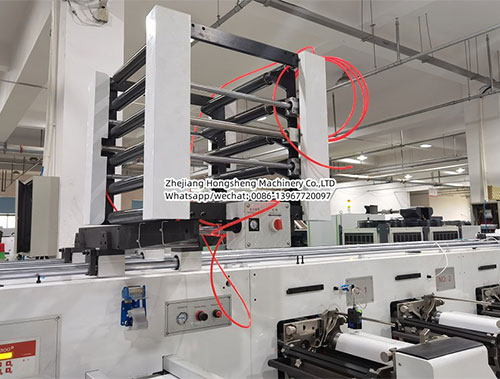

Independent Servo Drive: Servo motors independently control each printing unit, coupled with an electronic overprinting system to enable 360° precise phase adjustment and rapid order switching.

Intelligent & User-Friendly Operation: Integrated microcomputer control panel supports one-key parameter setup, fault diagnosis, and remote monitoring—reducing operational barriers and minimizing downtime.

High-Precision Multi-Color Printing: 4-color flexo units combined with an intelligent visual overprinting system, delivering ±0.1mm registration accuracy for accurate multi-color pattern alignment.

High-Speed Stable Production: Max speed of 150m/min, facilitating continuous roll-to-roll printing. Equipped with automatic tension control and fast plate change for substantial productivity gains.

|

Max.Web width |

350mm |

|

Max.printing width |

340mm |

|

Max.Unwind Diameter |

1050mm |

|

Max.Rewind Diameter |

1050mm |

|

Max.printing speed |

150m/min |

|

Printing Precision accuracy |

±0.1mm |

|

Rotary die cutting accuracy |

±0.15mm |

|

Rang of printing |

10”-24” |

|

Plate thickness |

1.14mm |

|

Max.label die cutting speed |

100m/min |

|

Pre –registration |

Datelogic Color sensor |

|

Material |

All materials except shrink film |

|

Thickness of material |

0.02mm—0.35mm |

GET A QUOTE