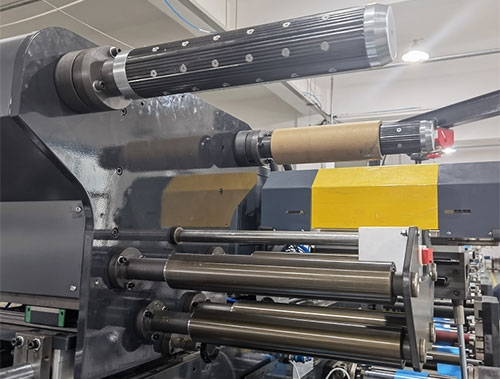

Hongsheng Automatic Label Flexo Printing Machine features a single servo drive system, Yaskawa control, and 8-color flexible configuration, delivering ±0.1mm printing precision, compatible with self-adhesive labels, paper, and other materials while enabling 24-hour continuous production via intelligent HMI touch screen and automatic tension control, ideal for daily chemical, food packaging, and pharmaceutical label printing.

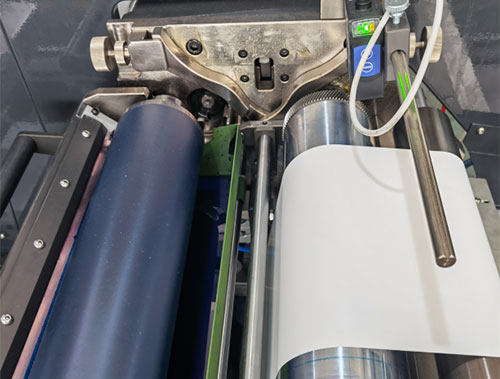

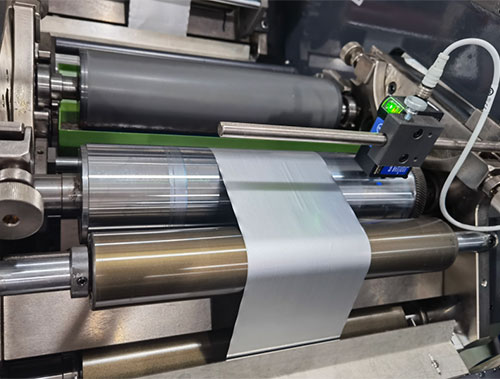

High Precision & Stable Performance: Adopts a single servo main motor with multi-axis servo control, ensuring consistent tension and exceptional overprint accuracy of ±0.1mm even during high-speed operation, meeting strict printing quality standards.

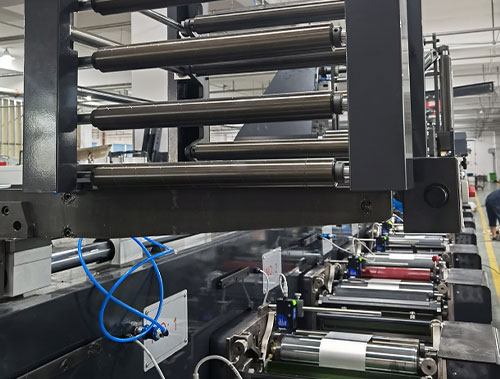

Versatile 8-Color Printing Capability: Features an 8-color flexible configuration that supports complex pattern printing (spot color, gradient, dot, etc.), perfectly adapting to diverse order requirements for customized printing.

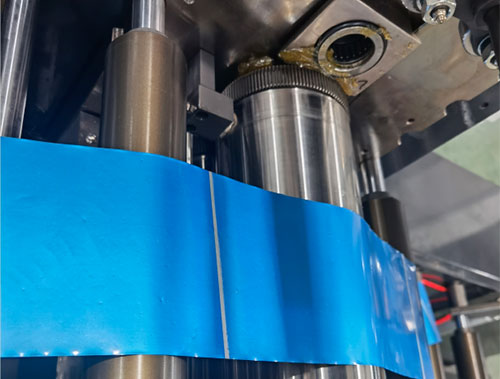

Wide Compatibility & Smart Automation: Compatible with film and paper substrates, ensuring high-quality outputs for diverse materials via temperature and pressure adjustment. Equipped with HMI touchscreen for parameter presets and automatic tension controller (anti-wrinkling), enabling 24/7 uninterrupted production effortlessly.

|

Max.Web width |

350mm |

|

Max.printing width |

340mm |

|

Max.Unwind Diameter |

1050mm |

|

Max.Rewind Diameter |

1050mm |

|

Max.printing speed |

150m/min |

|

Printing Precision accuracy |

±0.1mm |

|

Rotary die cutting accuracy |

±0.15mm |

|

Rang of printing |

10”-24” |

|

Plate thickness |

1.14mm |

|

Max.label die cutting speed |

100m/min |

|

Pre –registration |

Datelogic Color sensor |

|

Material |

All materials except shrink film |

|

Thickness of material |

0.02mm—0.35mm |

GET A QUOTE